Or you can write our sales team directly: Michael@cableharnessexpert.com

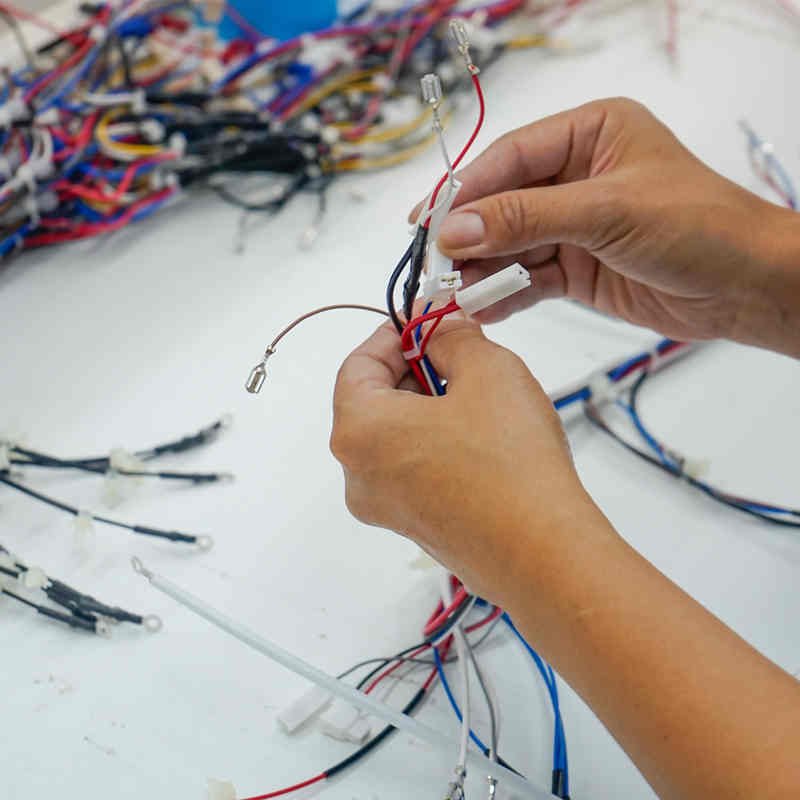

Our team is experienced in creating excellent custom eletrical wire harnesses.

Critical quality control policies are practiced in every step of the manufacturing process.

The critical and quality conductor materials are a MUST to ensure the power and signal transmission are designed to work efficiently.

Keeping a roll-running inventory of UL wires has helped us offer quick prototyping and manufacturing that our clients love.

1 The size, lengths, and shape must meet the layout of custom wire harness.

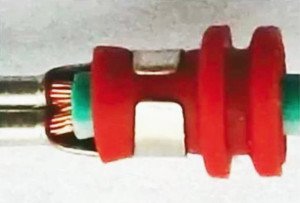

2, Installation positions have special requirements regarding waterproof design and manufacturing.

3, Most importantly, we find adapt solutions for shielding solutions regarding electronic devices and custom wire harnesses.

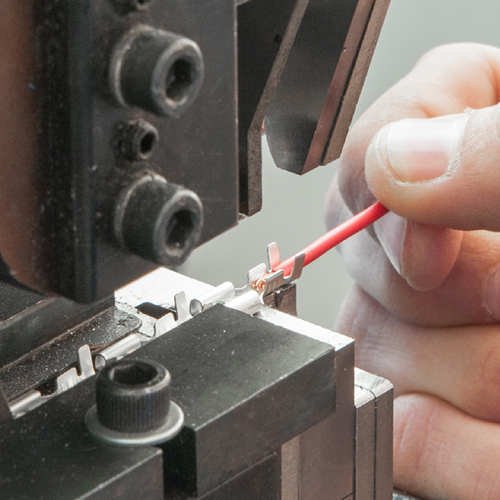

We hire the very best trained operators for this position.

There is a full inspection for every terminal crimped.

Terminals are the essential parts for power and signal continuity. There is no space for any potential defective error when processing crimping.

The terminals must be crimped in the correct position on insulations and conductors to ensure solid junctions.

Most defective crimping happens in poor pull-force! We ensure inspection of the force-test of each batch production.

Or, you could write our sales team: Michael@cableharnessexpert.com