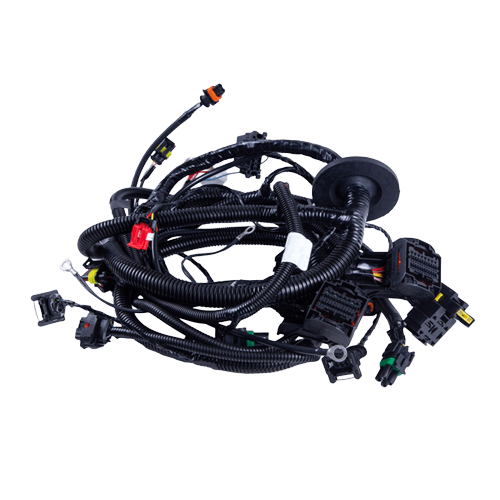

Wire harnesses, also known as wiring looms, assemblies, or cable assembly harnesses, are bundles of wires, cables, subassemblies, and other electrical components that are typically bound together using a range of exterior fasteners, including braids, expandable sleeving, military lacing, spinal wrap, and tie wraps. These wire harnesses are designed to transmit electricity for power or signaling purposes and are used in many industries to streamline and organize complex wiring systems. These wire harnesses can be easily modified to suit a range of industrial, commercial, and consumer applications, whether they are being used indoors or outdoors.

We are a professional manufacturers that build a wide range of vehicle cable assemblies and wire harnesses for well-known automobile manufacturers in China and abroad. We manufacture custom cable assemblies, wire harness assemblies for infotainment systems, and multimedia systems for any vehicles, electric vehicles, trucks, buses, and off-road vehicles.

Custom wire harnesses and cable assemblies are CHE’s specialty. Custom wire harnesses are designed and produced based on a particular application. They are customized to match the exact specifications of the equipment and can include various types of wires, connectors, terminals, and protective sheaths.

Custom battery cables are specialized electrical wires used in various industries, including automotive, photovoltaic energy storage, marine, etc. They are designed to meet the unique electrical requirements of battery systems found in all types of machines or systems. It is essential that they can carry high voltage and high current with ease and also possess strong resistance to a range of environmental conditions.

M-type connectors are circular connectors suitable for use in various European industries, including aerospace, automotive, communication, marine, medical equipment, and signal transmission equipment. CHE has developed several M series connectors and various over-molding toolings to provide flexible solutions for multiple applications. We will continue to grow in this field to meet clients’ requirements for industrial automation and process control systems by offering high-quality connector assemblies and solutions.

Vehicle CCTV cable accessories are one of the essential parts for vision safety systems that are installed in all kinds of vehicles, such as cars, trucks, tankers, school buses, and buses. We started producing cable assemblies for vehicle video monitors and cameras ten years ago and have accumulated rich technical and customer resources such as Stonkam, Mingshang, etc. We can quickly develop and produce various types of vehicle CCTV cables based on customer needs, helping them to get their ideas to market soon.

Custom over-molded cable assemblies are cable assemblies that are entirely integrated and seamlessly combine the cable and connector components to meet specific customer requirements. The over-molding process involves injecting molten material into a mold cavity, which, when cooled, conforms to the desired shape. Custom over-molded cable assemblies are widely used in nearly every industry and application while being able to withstand the demands of the most challenging environments.

Our custom wire assemblies outperform others thanks to our quality production.

CHE has state-of-the-art production facilities allow us to make high-quality wire harnesses and cable assemblies. Our automated equipment, competent team, and tight process controls ensure that our wiring looms are consistent, efficient, and error-free. Additionally, we are committed to continuous improvement and optimizing our production processes to meet the diverse needs of our clients while ensuring that all our wire cable harness assemblies meet the highest quality standards.

We offer comprehensive engineering services to assist in product development and production. We help clients achieve their engineering goals and meet the challenges of today’s fast-paced manufacturing industry. Additionally, we provide consulting services to help clients improve their manufacturing processes and reduce costs. Our services include:

We perform comprehensive in-house testing on our custom wire harnesses using advanced tools and equipment, such as electrical, mechanical, and environmental tests. Additionally, we collaborate with third-party testing companies to ensure compliance with industry standards and regulations. Every wiring cable assembly and harness undergoes testing and passes strict quality checks before being packaged and shipped!

Welcome to CHE, a professional manufacturer of custom cable assemblies and wire harnesses established in 1999. As an ISO and ITAF16949-certified company, we have built a reputation for producing high-quality wire and cable assemblies for various industries.

We can offer both low-volume, high-mix cables, and high-volume cables, meeting the diverse needs of our customers. We are proud of our various manufacturing capabilities, which enable us to provide custom solutions for any industrial cables, OEM cables, or custom cables of any design.We are dedicated to reviewing and manufacturing custom wire harnesses and cable assemblies that meet each customer’s needs.

We specialize in custom cable and wire harness assemblies for various industries, including aerospace, automotive, medical, and industrial. Our team has the skills and experience to handle both simple wire assemblies and complex multi-conductor cable harnesses.

At CHE, we are committed to providing the best possible service to our customers, such as cable assembly manufacturing, prototyping, quick-turn, certification, testing, and on-time delivery to ensure your project is completed successfully.

Thank you for considering CHE, China’s professional custom cable assemblies and wire harness manufacturer. Get in touch with us today to request a quote.

Or, you may write our sales team: Michael@cableharnessexpert.com

Or, you could write our sales team: Michael@cableharnessexpert.com